- Home

- /

- News

- /

- Industry News

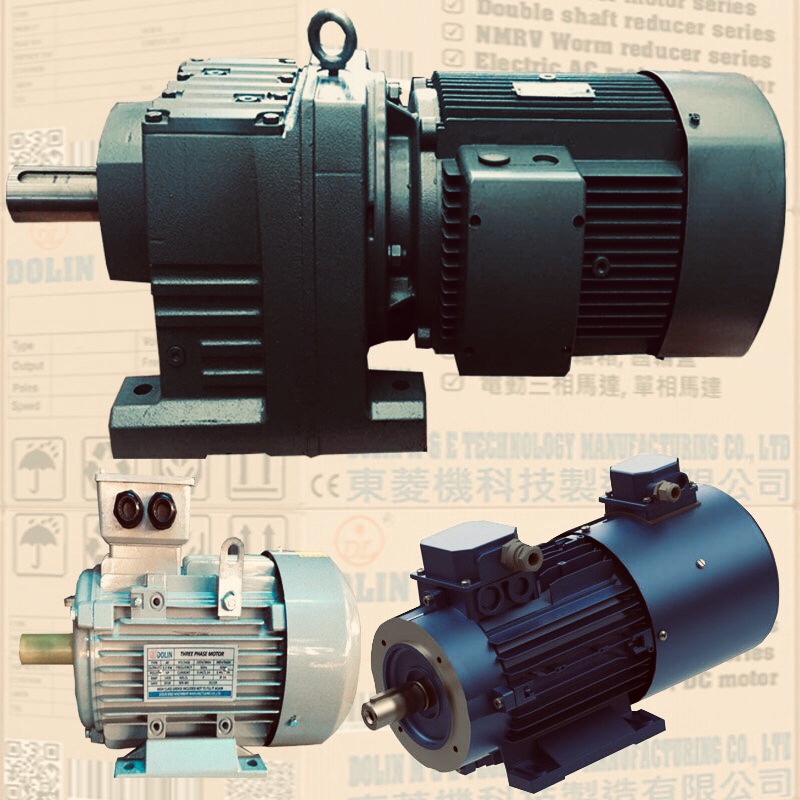

Motor and Gearbox

Originally, gear trains and the structure that houses them (called gearheads, gear reducers or gearboxes) were created for two following main reasons:

1. To increase motor torque.

2. To enable more adjustments to be made to a motor’s speed.

However, advancements in technology has enabled gearboxes to make additional progress in permissible inertia and vibration reduction. These changes are largely dependent upon the types of gearwheels operating inside in each gearbox.

Gears types:

Spur: a high-efficiency, straight-toothed gearwheel in which the wheel axis and teeth run parallel to each other.

In other terms,this is what typically comes to mind when a person thinks of a gear. It’s the simplest and most common type and is what you would find if you tore apart your wristwatch or opened up your washer and dryer set.

Helical: a more expensive, high-efficiency gearwheel with angled teeth that allow for smoother and quieter interaction of the moving gears.

In a simple breakdown, this means that the angle (usually somewhere between 1°- 45°) allows for a more gradual connection between gears, because unlike the spur gears, helical ones slide instead of click. This is why a car full of passengers, which has many helical gears, rattles less than a clothes dryer full of laundry.

Worm: a non-backdrivable gear and gearwheel (depending on gear ratio and load, they will be incapable of reverse motion) that are held together by friction and is ideal for heavy shock load applications.

Simply put, this spiraled gear part (which looks much like the threaded body of a screw) has more teeth in contact than a helical or spur gear, so it more successfully combats sudden changes in movement.

The threaded component, the steel worm, interacts with a worm gearwheel (which looks like an actual gear instead of a screw and is typically bronze or copper) in order for movement to occur.

Bevel: a spiral-, straight-, or hypoid-shaped gearwheel specifically designed to shift the rotational direction of a shaft.

More or less this type is either a straight- or angle-toothed gear that is used when a right-angle orientation is necessary.

A bevel gear’s 90° design uses less room than other gear types, so when placed in applications such as car differentials or power transmissions, more space is available for passengers and cargo storage.

Because of these fluctuating factors, Dolin motor offers various customizations,such as gear ratio modifications to help make this process easier and to aid in the selection of the optimal gearbox-to-application pairing.

Newer articles

- What is a Current Transformer? (22/11/2017)

- Determining Gear Ratio and Its Importance (22/11/2017)

- Different types of motors and their use (22/11/2017)

- Selecting Motors for Industrial Applications (22/11/2017)

- Speed reducers: main applications and how to improve their operation (18/11/2017)

- When Does Poor Power Quality Cause Electronics Failures? (12/11/2017)

- The different types of gears (09/11/2017)

- Advantages and disadvantages of different types of gears (01/09/2018)

- Why electric motors fail (12/11/2017)

- What are Brushless DC Motors (31/05/2019)

Older articles

- Gearbox Motors vs Integrated Gearmotors (16/04/2008)

- AC or DC? brushed DC or brushless DC Gear Motor? (24/04/2008)

- Gear motor Selection: Gearbox Reducer Housing Materials (10/10/2017)

- Dolin seeks help in identifying poor “reliability” in electric motors (02/02/2007)

- WHAT TO CONSIDER WHEN SELECTING A GEAR REDUCER OR GEAR MOTOR (22/11/2012)

- Applying Gear Ratios to DC Motor Systems (08/11/2013)

- What Does Gear Reduction (Gearbox) actually mean for DC gearbox motors? (22/11/2012)

- 4 Common Worm Gear Applications (11/11/2010)

- What is a Reduction Gear? (09/10/2009)

- What is a Gear Reducer? (29/10/2017)

Join